Contour process - simple and reliable

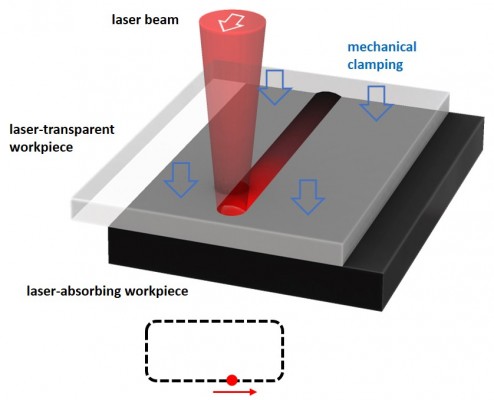

In the contour process, the laser is focused to a spot and is moved once along the desired welding contour. The plastic is only heated and melted over a short distance before it cools down again.

A spot optic with a larger or smaller spot and working distance depending on the focusing lens is used normally.

Servo axes in x and y direction are employed for the movement along the contour. If the weld seam has different heights an additional z-axis supplements the motion system. The welding contour can easily be changed by loading a new contour into the axis control system.

Welding speeds are typically in the range of a few cm/s.

For process control, a pyrometer can be used in the spot optic that detects a temperature signal from the weld seam.

Two special variants of the contour process are

- Ball contour process

- Rotation contour process