Medical Technology

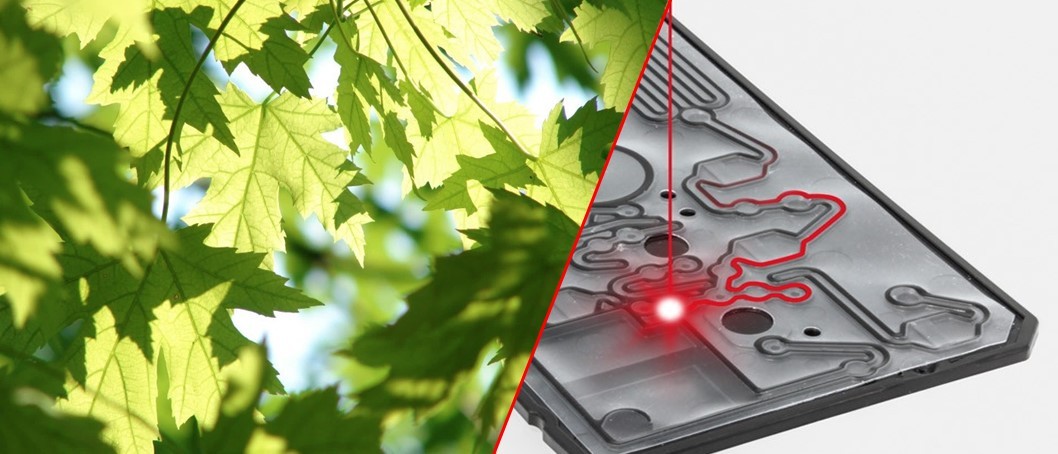

- Diagnostic cartridges from simple layouts to complex micro/macro-fluidic structures for e.g. testing Corona COVID-19

- Pump housing and hose connections

- Sample receptables

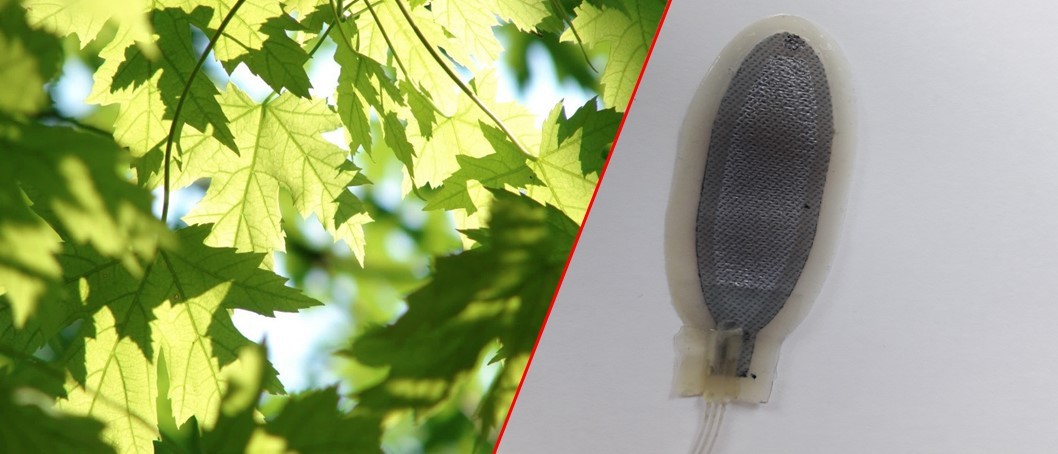

- Membranes or filters on carriers or in housings (e.g. dialysis)

- Housing of sensors, displays, operating units

- Consumables and disposables

- Packaging of medical devices or consumables.

For product in medical technology, laser welding of plastics primarily scores with precise welding seams and clean joints.

Since many applications for laser welding in medical technology involve the transport of liquids, it is important on the one hand to weld tightly, but on the other hand no melt or particles must be produced that can block fine channels. Therefore, the contour process is often selected whereby the weld seam can be traced by an axis system or a Glavo scanner.

Due to the very good localization of the heating during laser welding, only the weld seam itself is heated and not nearby areas, which may contain heat-sensitive reagents.

Membranes and filters must not be mechanically damaged by the welding process so that laser welding has advantages against ultrasonic or friction welding.

In medical technology, soft plastic parts are also frequently used, which can also be easily welded with the laser. Such elastomers are used in particular for consumables or disposables.

For electronic modules in medical technology, the same advantages as for the entire electronics industry are decisive.

In the case of medical packaging, the clean process without particles can be an important point to favor laser welding or the packaging can be individually adapted.