Simultaneous - in one shot

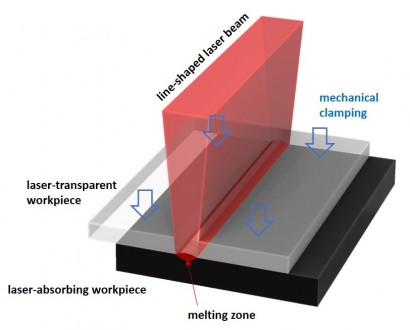

The laser beam is shaped by special optics in such a way that it corresponds to the geometry of the welding contour. The laser then only needs to be switched on and off. Welding takes place in a single shot of laser energy without the laser having to move along the weld seam. This enables very short cycle times.

Simultaneous welding is always limited to a certain contour. For a new contour, the optics or individual optical elements must be replaced.

Typically, the simultaneous process is used to weld very large quantities of parts with always the same geometry.

As with quasi-simultaneous welding, the entire weld seam is melted simultaneously. Again collapse measurement for quality analysis or process control is possible.

The simplest geometries for simultaneous welding are lines and rectangular surfaces. Specific optics can also be used to create more complex geometries, such as

Another possibility would be to simulate the welding contour with an optical fiber bundle with the same power from each individual fiber. This method requires complex and expensive tooling with very limited flexibility of the contour. It has been patented by the company Branson and is therefore not offered by ProByLas AG.