Welding circumference - rotation

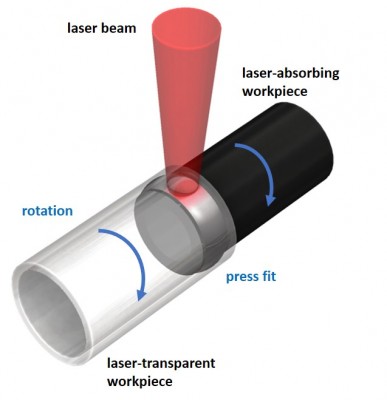

When welding cylindrical parts at their circumference, such as a tube with a connector, the component can be rotated in the laser beam for welding. Alternatively, the optics can also be rotated around the stationary part.

The welding process corresponds to a contour or quasi-simultaneous welding process, depending on whether only one or many rotations are required. In contrast to simultaneous circumferential welding with radial optics, a pyrometer can be used in the rotation process for process and quality control.

The circumferential clamping pressure between the two cylindrical components cannot be applied by an external mechanical clamping unit, but must be applied via a press fit between the two components.