Polymers and plastics

Plastics consist primarily of polymers, which are a long sequence of molecular units (monomers) bound to each other. In a polymer chain, different molecular unit can also be combined (co-polymer) or different polymer chains mixed together (blend). Depending on the combination, different material properties can be achieved.

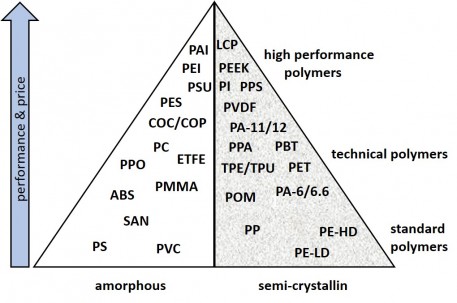

Polymers are often divided into amorphous crystal-clear types and semi-crystalline ones, which appear opaque due to the crystallites of the polymer chains. A distinction is also frequently made between standard polymers, technical polymers and high-performance polymers.

By mixing additives to the polymers, the plastics properties can be further changed. In contrast to metal alloys, the concentration of additives is much higher and is typically in the one- or two-digit percentage range.

Additives are typically:

- Colorants

- Mineral fillers

- Fibers such as glass or carbon fibers

- Flame retardants

- Plasticizers

The admixture of dyes is of particular importance for laser welding. It enables one part to be laser-transparent and the other laser-absorbing.

Mineral fillers and fibers scatter the light and reduce the transparency for the laser in the upper part. Welding can no longer be possible with high concentrations of mineral fillers or fibers and for thicker parts.

Flame retardants and plasticizers can change the melting behavior of the polymer and make welding more challenging. For example, they can evaporate and foam before or during melting of the plastic, so that a good welding joint is no longer possible.