Line optics - for mask and plane welding

An additional micro-lens array can be used to generate a linear laser beam from a spot. Depending on the lens combination, line lengths of 12-60 mm are possible.

Line optics in combination with a translation axis are suitable for welding complete areas of plane parts.

The line optics can also be used for a simultaneous process when a single line has to be welded.

Most frequently the line optics is employed for mask welding. A mask with the desired weld contour is introduced above the parts and shadows areas, which should not be welded. Complex structures can be welded in a short time by just a single sweep of the line optics.

Collimated laser line for mask welding

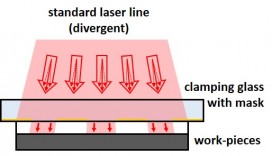

With the normal laser line, the beam diverges further with the working distance. The shadow cast from the mask onto the work-piece thus increases along the laser line, which can play an important role with thicker upper work-pieces. For larger distances from mask to weld seam, this distortion must therefore be pre-compensated in the mask design.

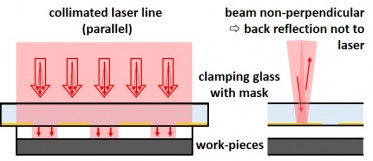

The better solution is the collimated laser line. The diverging laser line is parallelized again (=collimated) by an additional lens above the mask. The shadow cast by the mask no longer diverges and the mask structure does not have to be corrected.

Additionally with collimated line optics, the laser beam is not incident perpendicularly on the mask, but at a small angle, so that the back reflection of the mask cannot route back to the laser and damage it.

The collimated line optics of ProByLas AG has a length of 40 mm and a width of about 1 mm.

The remaining beam divergence over the line length is <3°.

The direction of incidence of the laser beam is inclined by about 2° to prevent a back reflection from the mask into the laser source.

Other collimated line lengths are available on request.

Links technology

Photos line optics

normal laser line with basic optics

normal laser line with advanced optics

collimated laser line optics