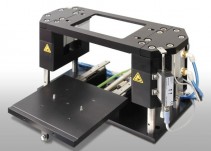

Modula Assembly Lab - for laboratory work

The Modula Assembly Lab is a compilation of Modula components for open operation, typically in an application laboratory. It is a ready-for-use combination similar to a Turnkey system but without a protective housing. Therefore it can only be operated with laser safety goggles without any other additional safeguards.

A Modula Assembly consists of a laser unit and a base plate with clamping unit, motion system (scanner or axes) and optics. A warning lamp is connected to the laser unit, which flashes when laser operation is enabled. A box with start button and manual interlock switch is also attached to the laser unit.

In addition to laser safety by wearing laser safety goggles, safety against squeezing and crushing by the clamping unit or moving axes must also be ensured. Either by monitored safety guards or by appropriately trained specialists, who know the dangers and how to avoid them.

Possbile combinations for a Modula Assembly Lab are:

- Contour welding: Laser unit with xy-axes system, spot optics, and pneumatic clamping unit (see above). Pneumatic supply and control of the clamping unit on panel behind clamping unit and axes.

- Mask welding of e.g. microfluidic chips: Laser unit with x-axis, line optics, and pneumatic clamping unit with mask holder..

- Tube connections radial: Laser unit with radial optics - possibly with special holder, which closes the opening of the radial optics laser safe, so that no laser safety glasses are necessary.

- Quasi-simultaneous welding: Laser unit with scanner optics and clamping unit, including displacement sensors to measure the welding collapse.